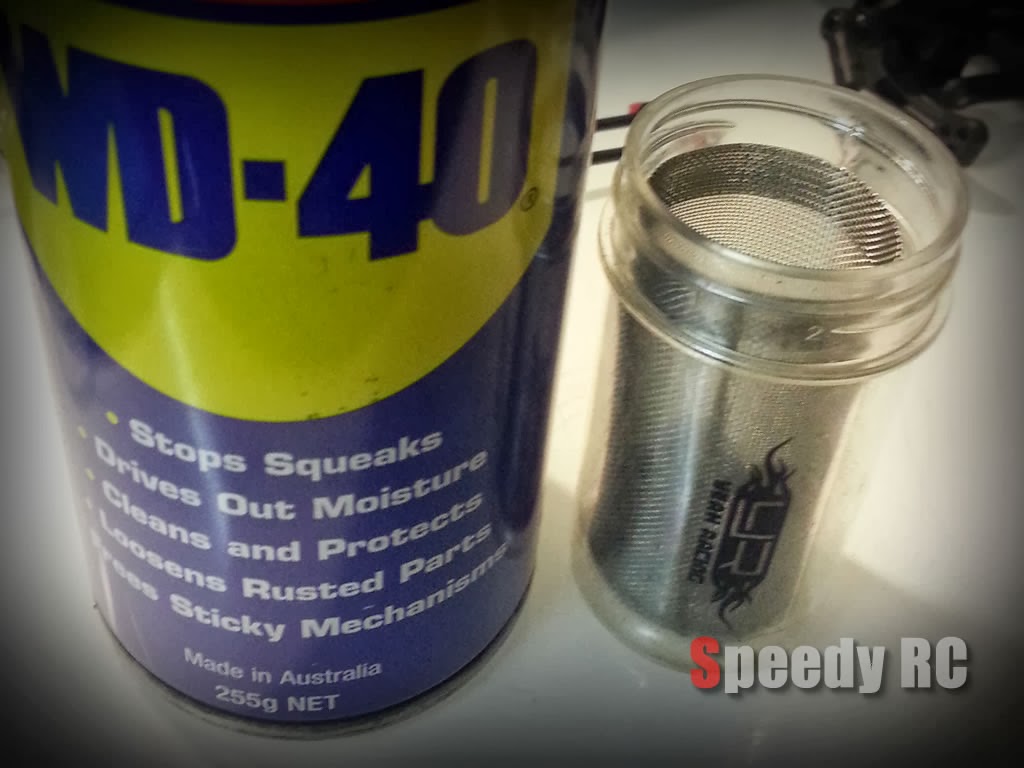

Now, as always, Pics up first.

Let's take all 4 dampers/Shock Absorbers out from car kit.

Before maintain the damper and shocks, let's check the swing arm first.

Lift both front and rear arms up side by side, verify if other side can lift up freely as well.

If not, you probably got something blocking the arm from moving. you have to check suspension blocks, pivot cups, arm pins to find out if anything broken. Re-lubricate them if needed.

If the Arm cannot swing freely, it will provide negative effect to the function of Shock/Dampers and Anti-roll bars, so do the weight balance and weight transfer.

Now, if everything going alright, let's deal with this damping systems.

We need to clean up the surface of all 4 shock/dampers with brush.

After clean up, we have to squeeze the shock-damper to verify if it needs rebuild.

Put your ear close, if you hear bubble or friction sound when squeezing the shock. You are more than likely have to rebuild the shock.

Now, let's take the shock damper apart:

First of all, release the spring by remove the down stopper cap.

If you got a chance, you can also test the re-bound situation of damper as well.

squeeze to the very end then release, see if it can rebound back to pre-load distance. e.g. 10%,50% or 100%.

Well, if you set it up as 0% rebound, you don't have to do this test.

OK, now twist the top shock cap and open it. For the damper fail to rebound to preset value or got friction sound when squeezing, you will probably found the shock oil get dark and some load of bubbles inside. This is because the damper is no longer sealed and you definitely need to have it rebuild.

Pour out the oil inside, use shock shaft clamp to hold he shock shaft. Twist the shock end to release itself.

Be careful to not damage or scratch the shock shaft.

After you take the bottom shock end out, you have to push the shock shaft in from bottom and take it out from upper side.

After that, take the bottom sealer Alum cap apart, take out the shaft guide and O-Ring, clean the dust if needed. Verify if there is any wear out part, If O-Ring is deform, replace it.

Then we put the O-Ring into a small bottle of silicone shock oil.

You don't have to take piston apart unless you have to replace with another type or it is damaged (highly unlikely). But you do have to verify if the shock shaft is bent. Replace if needed.

Now, let's carry on the rebuild process, as always, we recommend green slime from AE to seal the damper with best result.

Before you put the Shaft Guide into the bottom of damper, apply a dip of green slime to the inside.

Apply a little bit of Green Slime onto the inside of O-Ring as below.

Befrore cover the O-Ring with Shaft Cap, apply a bit of shock oil on it to guarantee it is fully sealed.

Then tighten up the Alum Shock Bottom Cap.

Dip a bit of shock oil into the inside of shock body, insert the shock shaft with piston from inside and push out.

Now, twist back Shock Bottom Connector, Mark down the length of each shock shaft with Digital Caliper. You have to build each shock with exact same length.

Fill 80-90% of shock oil into the shock body and put it into Damper Oil Remover device.

Repeat the same process on each shock. Now we have all four shock-damper ready.

Suck the bubbles out with Damper Oil Remover, you could see the bubbles rising and explore quickly from shock body. Repeat the sucking process a couple times until you are sure that there is no more air bubbles inside by move the shock shaft up and down.

PS. If you do not have Damper Oil Remover on hand, never mind, move the shock shaft up and down to release bubbles and wait 5-10 minutes and then repeat. The purpose of doing so is to ensure the shock is fully sealed. Damper Oil Remover can make the whole process a lot quicker.

Now, it is time to pre-set the rebound value. We recommend you use this Aluminum Damper Rebound Adjusting Tool from YR. You can pre-set the same value of rebound of each shock-damper precisely.

Now, you have 4 shock ready with the same pre-set rebound value.

Top-up shock oil into the shock body and cover it with Oil Sealer Cap, blend the cap evenly, don't worry about the oil that spill over, just clean it later with tissue. This process is to make sure there is no air bubbles remain on the top of shock-damper.

Put the Shock Top Connector onto the cap and cover the Shock Body Cap, twist is to sealed.

Final check out: we can squeeze the shock shaft to test the rebound of each shock. If it has been setup correctly, you will got same rebound for 4.

Set the spring back then all done!

Thanks for watching.

<<-Visit SpeedyRC Online eStore